Ha theknoloji ea laser e matla a phahameng e ntse e tsoela pele ka potlako, Li-Laser Diode Bars (LDBs) li se li sebelisoa haholo ts'ebetsong ea indasteri, opereishene ea bongaka, LiDAR, le lipatlisiso tsa mahlale ka lebaka la matla a tsona a phahameng le tlhahiso e phahameng ea khanya. Leha ho le joalo, ka ho kopanngoa ho ntseng ho eketseha le hona joale ea ts'ebetso ea li-chip tsa laser, liphephetso tsa taolo ea mocheso li ntse li hlahella haholoanyane - li ama ka kotloloho botsitso ba ts'ebetso le bophelo ba laser.

Har'a maano a fapaneng a taolo ea mocheso, ho Koetlisa ka Mocheso oa ho Kopana ho hlahella e le e 'ngoe ea mekhoa ea bohlokoa ka ho fetisisa le e sebelisoang haholo ho paketeng ea li-bar tsa laser diode, ka lebaka la sebopeho sa eona se bonolo le ho khanna ha mocheso o phahameng. Sengoloa sena se hlahloba melao-motheo, lintlha tsa bohlokoa tsa moralo, khetho ea thepa, le mekhoa ea kamoso ea "tsela ena e khutsitseng" ea taolo ea mocheso.

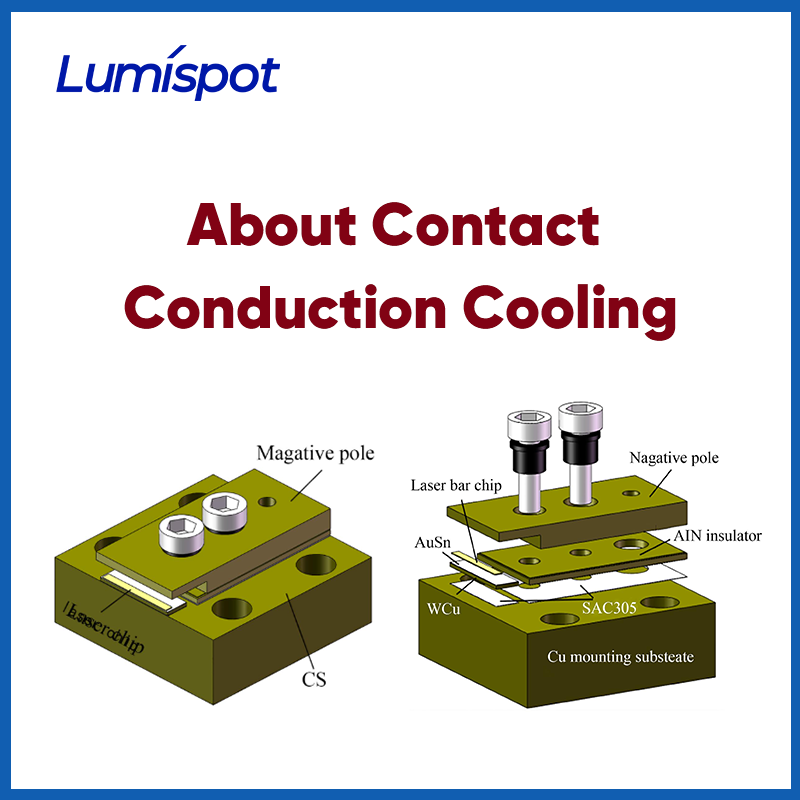

1. Melao-motheo ea ho Pholisa ho Tsamaisa Motsoako oa ho Kopana

Jwalo ka ha lebitso le bontsha, phodiso ya conduct conduction e sebetsa ka ho theha kgokagano e tobileng pakeng tsa chip ya laser le sinki ya mocheso, e nolofalletsang phetiso e sebetsang hantle ya mocheso ka thepa e phahameng ya conductivity ya mocheso le ho qhalana ka potlako tikolohong ya kantle.

①The HjaPath:

Ka har'a bare e tloaelehileng ea laser diode, tsela ea mocheso ke e latelang:

Chip → Lera la Solder → Submount (mohlala, koporo kapa ceramic) → TEC (Thermoelectric Cooler) kapa Heat Sink → Tikoloho e Tikolohang

②Likaroloana:

Mokhoa ona oa ho pholisa o na le likarolo tse latelang:

Phallo e matla ea mocheso le tsela e khutšoanyane ea mocheso, e fokotsang mocheso oa li-junction ka katleho; Moralo o moqotetsane, o loketseng sephutheloana se senyenyane; Ho tsamaisa lintho ka tsela e sa sebetseng, ha ho hloke li-loops tse rarahaneng tsa ho pholisa tse sebetsang.

2. Lintlha tsa Bohlokoa tsa Moralo bakeng sa Tshebetso ea Thermal

Ho netefatsa hore ho phodiswa ha contact conduction ho sebetsa hantle, dintlha tse latelang di lokela ho shejwa ka hloko nakong ya moralo wa sesebediswa:

① Khanyetso ea Thermal ho Solder Interface

Ho tsamaisa mocheso ha lera la solder ho bapala karolo ea bohlokoa ho hanyetseng mocheso ka kakaretso. Litšepe tse tsamaisang mocheso tse phahameng joalo ka alloy ea AuSn kapa indium e hloekileng li lokela ho sebelisoa, 'me botenya le ho tšoana ha lera la solder li lokela ho laoloa ho fokotsa litšitiso tsa mocheso.

② Khetho ea Thepa e ka Tlase

Lisebelisoa tse tloaelehileng tsa submount li kenyelletsa:

Koporo (Cu): E tsamaisa mocheso ka lebelo le phahameng, e theko e tlase;

Koporo ea Tungsten (WCu)/Koro ea Molybdenum (MoCu): E lumellana hantle le li-chip tsa CTE, e fanang ka matla le ho tsamaisa motlakase;

Aluminium Nitride (AlN): Sethibela-mollo se setle sa motlakase, se loketse lits'ebetso tsa motlakase o phahameng.

③ Boleng ba ho Kopana le Bokaholimo

Ho ba thata ha bokaholimo, ho ba bataletse, le ho ba mongobo ho ama ka kotloloho bokgoni ba phetisetso ya mocheso. Ho bentsha le ho penta ka kgauta hangata di sebediswa ho ntlafatsa tshebetso ya ho kopana le mocheso.

④ Ho Fokotsa Tsela ea Thermal

Moralo oa sebopeho o lokela ho ikemisetsa ho khutsufatsa tsela ea mocheso pakeng tsa chip le sinki ea mocheso. Qoba mekhahlelo e sa hlokahaleng ea thepa e mahareng ho ntlafatsa katleho ea ho qhala mocheso ka kakaretso.

3. Litaelo tsa Nts'etsopele ea Nakong e Tlang

Ka mokhoa o ntseng o tswela pele wa ho etsa hore motlakase o be bonolo le ho ba matla a mangata, theknoloji ya ho phodisa ya ho tsamaisa motlakase e ntse e fetoha ka ditsela tse latelang:

① Li-TIM tse Kopantsoeng tsa Melara e Mengata

Ho kopanya ho tsamaisoa ha mocheso ka tšepe le ho buffer ho tenyetsehang ho fokotsa khanyetso ea sebopeho le ho ntlafatsa ho tšoarella ha potoloho ea mocheso.

② Sephutheloana sa Sinki ea Mocheso se Kopaneng

Ho rala li-submount le li-heat sink e le sebopeho se le seng se kopaneng ho fokotsa li-contact interface le ho eketsa katleho ea phetisetso ea mocheso boemong ba sistimi.

③ Ntlafatso ea Sebopeho sa Bionic

Ho sebelisa libaka tse nang le sebopeho se senyenyane tse etsisang mekhoa ea tlhaho ea ho qhala mocheso—joalo ka “ho tsamaisa mocheso joalo ka sefate” kapa “lipaterone tse kang sekala”—ho ntlafatsa ts'ebetso ea mocheso.

④ Taolo ea Thermal e Bohlale

Ho kenyelletsa di-sensor tsa mocheso le taolo ya matla a feto-fetohang bakeng sa taolo ya mocheso o ikamahanyang le maemo, ho atolosa nako ya tshebetso ya sesebediswa.

4. Qetello

Bakeng sa li-laser diode tse matla haholo, taolo ea mocheso ha se phephetso ea botekgeniki feela—ke motheo oa bohlokoa oa ts'epo. Ho pholisa ha conduction ea contact, ka litšobotsi tsa eona tse sebetsang hantle, tse butsoitseng le tse theko e tlaase, e ntse e le e 'ngoe ea litharollo tse kholo tsa ho qhala mocheso kajeno.

5. Mabapi le Rona

Ho Lumispot, re tlisa boiphihlelo bo tebileng ba ho paka diode tsa laser, tlhahlobo ea tsamaiso ea mocheso, le khetho ea thepa. Sepheo sa rona ke ho fana ka litharollo tsa laser tse sebetsang hantle le tse tšoarellang nako e telele tse etselitsoeng litlhoko tsa hau tsa kopo. Haeba u ka rata ho ithuta ho eketsehileng, re u amohela ka mofuthu hore u ikopanye le sehlopha sa rona.

Nako ea poso: Phuptjane-23-2025