Ingolise ho Mecha ea Rona ea Litaba tsa Sechaba bakeng sa Poso e Potlakileng

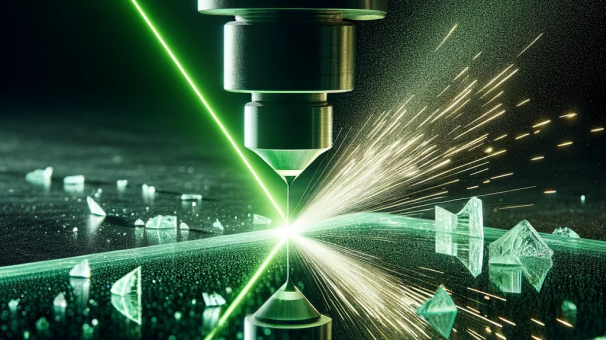

Selelekela sa ho Sebetsa ka Laser ho Tlhahisong

Theknoloji ea ho sebetsana le laser e bile le nts'etsopele e potlakileng 'me e sebelisoa haholo mafapheng a fapaneng, joalo ka lifofane, likoloi, lisebelisoa tsa elektroniki, le tse ling. E bapala karolo ea bohlokoa ho ntlafatseng boleng ba sehlahisoa, tlhahiso ea basebetsi, le boiketsetso, ha ka nako e ts'oanang e fokotsa tšilafalo le tšebeliso ea thepa (Gong, 2012).

Ho Sebetsa ka Laser ka Lisebelisoa tsa Tšepe le Tse seng tsa Tšepe

Tšebeliso ea mantlha ea ts'ebetso ea laser lilemong tse leshome tse fetileng e bile thepa ea tšepe, ho kenyeletsoa ho seha, ho tjheseletsa le ho koahela. Leha ho le joalo, tšimo ena e ntse e atoloha ho ea ho thepa e seng ea tšepe joalo ka masela, khalase, polasetiki, li-polymer le li-ceramic. E 'ngoe le e 'ngoe ea thepa ena e bula menyetla liindastering tse fapaneng, leha ba se ba ntse ba e-na le mekhoa ea ts'ebetso e thehiloeng (Yumoto et al., 2017).

Liphephetso le Mekhoa e Mecha ea ho Sebetsa Khalase ka Laser

Khalase, ka ts'ebeliso ea eona e pharaletseng liindastering tse kang tsa likoloi, tsa kaho le tsa elektroniki, e emela sebaka sa bohlokoa bakeng sa ts'ebetso ea laser. Mekhoa ea setso ea ho seha khalase, e kenyeletsang lisebelisoa tse thata tsa alloy kapa daemane, e lekanyelitsoe ke bokhoni bo tlase le mahlakore a masesaane. Ka lehlakoreng le leng, ho seha ka laser ho fana ka mokhoa o mong o sebetsang hantle le o nepahetseng haholoanyane. Sena se bonahala haholo-holo liindastering tse kang tlhahiso ea li-smartphone, moo ho seha ka laser ho sebelisetsoang likoahelo tsa lense ea khamera le li-skrini tse kholo tsa ponts'o (Ding et al., 2019).

Ts'ebetso ea Laser ea Mefuta ea Khalase ea Bohlokoa bo Holimo

Mefuta e fapaneng ea khalase, joalo ka khalase ea optical, khalase ea quartz, le khalase ea safire, li hlahisa liphephetso tse ikhethang ka lebaka la tlhaho ea tsona ea ho robeha habonolo. Leha ho le joalo, mekhoa e tsoetseng pele ea laser joalo ka femtosecond laser etching e nolofalitse ts'ebetso e nepahetseng ea thepa ena (Sun & Flores, 2010).

Tšusumetso ea Wavelength Mekhoeng ea Theknoloji ea Laser

Bolelele ba leqhubu la laser bo susumetsa ts'ebetso haholo, haholo-holo bakeng sa thepa e kang tšepe ea sebopeho. Li-laser tse ntšang mahlaseli a kotsi libakeng tsa infrared tse bonahalang, tse haufi le tse hole li hlahlobiloe bakeng sa matla a tsona a bohlokoa a ho qhibiliha le ho fetoha mouoane (Lazov, Angelov, & Teirumnieks, 2019).

Litšebeliso tse Fapaneng tse Thehiloeng ho Wavelengths

Khetho ea bolelele ba leqhubu la laser ha se ntho e sa reroang empa e itšetlehile haholo ka thepa ea thepa le sephetho se lakatsehang. Mohlala, li-laser tsa UV (tse nang le bolelele ba leqhubu bo bokhutšoanyane) li ntle haholo bakeng sa ho betla le ho taka ka nepo, kaha li ka hlahisa lintlha tse ntle haholoanyane. Sena se etsa hore li be ntle bakeng sa liindasteri tsa semiconductor le microelectronics. Ka lehlakoreng le leng, li-laser tsa infrared li sebetsa hantle haholo bakeng sa ts'ebetso e teteaneng ea thepa ka lebaka la bokhoni ba tsona ba ho kenella ka botebo, e leng se etsang hore li lokele lits'ebetso tse boima tsa indasteri. (Majumdar & Manna, 2013). Ka mokhoa o ts'oanang, li-laser tse tala, tseo hangata li sebetsang ka bolelele ba leqhubu la 532 nm, li fumana sebaka sa tsona lits'ebetsong tse hlokang ho nepahala ho hoholo ka tšusumetso e fokolang ea mocheso. Li sebetsa haholo-holo li-microelectronics bakeng sa mesebetsi e kang ho etsa lipaterone tsa potoloho, lits'ebetsong tsa bongaka bakeng sa mekhoa e kang photocoagulation, le lefapheng la matla a nchafatsoang bakeng sa tlhahiso ea lisele tsa letsatsi. Bophahamo bo ikhethang ba leqhubu la leqhubu la li-laser tse tala bo boetse bo li etsa hore li lokele ho tšoaea le ho betla lisebelisoa tse fapaneng, ho kenyeletsoa polasetiki le litšepe, moo phapang e phahameng le tšenyo e fokolang ea bokaholimo li lakatsehang. Ho ikamahanya hona ha li-laser tse tala ho totobatsa bohlokoa ba khetho ea bolelele ba leqhubu theknolojing ea laser, ho netefatsa liphetho tse ntle bakeng sa lisebelisoa le lits'ebetso tse itseng.

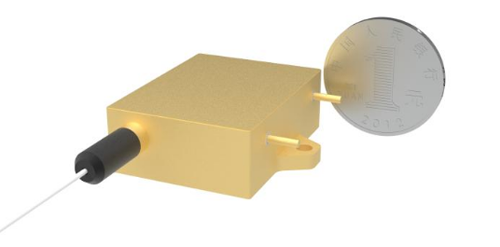

TheLesetara e tala ea 525nmke mofuta o itseng oa theknoloji ea laser e khetholloang ka ho ntšoa ha khanya e tala e ikhethang ho bolelele ba maqhubu ba li-nanometer tse 525. Li-laser tse tala ho bolelele bona ba maqhubu li fumana lits'ebetso ho retina photocoagulation, moo matla a tsona a phahameng le ho nepahala li leng molemo. Li boetse li ka ba molemo ts'ebetsong ea thepa, haholo-holo masimong a hlokang ts'ebetso e nepahetseng le e fokolang ea ts'ebetso ea mocheso..Nts'etsopele ea li-diode tse tala tsa laser holim'a substrate ea c-plane GaN ho ea ho maqhubu a malelele a 524–532 nm e tšoaea tsoelo-pele e kholo theknolojing ea laser. Nts'etsopele ena e bohlokoa bakeng sa lits'ebetso tse hlokang litšobotsi tse itseng tsa maqhubu a bolelele ba leqhubu.

Mehloli ea Leqhubu le Tsoelang Pele le ea Lesetara e Notletsoeng

Maqhubu a sa khaotseng (CW) le mehloli ea laser ea quasi-CW e kentsoeng mohlala maemong a fapaneng a maqhubu a kang near-infrared (NIR) ho 1064 nm, e tala ho 532 nm, le ultraviolet (UV) ho 355 nm li nahanoa bakeng sa lisele tsa letsatsi tse khethang ho sebelisa laser. Maqhubu a fapaneng a maqhubu a na le litlamorao bakeng sa ho ikamahanya le maemo le katleho ea tlhahiso (Patel et al., 2011).

Li-Laser tsa Excimer bakeng sa Lisebelisoa tsa Sekhahla sa Lebanta le Sephara

Li-laser tsa Excimer, tse sebetsang ka bolelele ba UV, li loketse ho sebetsana le thepa e nang le lekhalo le leholo joalo ka khalase le carbon fiber-reinforced polymer (CFRP), tse fanang ka ho nepahala ho hoholo le tšusumetso e fokolang ea mocheso (Kobayashi et al., 2017).

Nd:YAG Lasers bakeng sa Likopo tsa Liindasteri

Li-laser tsa Nd:YAG, ka ho ikamahanya ha tsona le maemo mabapi le ho lokisa bolelele ba leqhubu, li sebelisoa lits'ebetsong tse fapaneng. Bokhoni ba tsona ba ho sebetsa ka bobeli ba 1064 nm le 532 nm bo lumella ho tenyetseha ha ho sebetsoa thepa e fapaneng. Mohlala, bolelele ba leqhubu ba 1064 nm bo loketse ho betla ka botebo holim'a litšepe, ha bolelele ba leqhubu ba 532 nm bo fana ka ho betla ka holimo holimo holim'a polasetiki le litšepe tse koahetsoeng. (Moon et al., 1999).

→Lihlahisoa tse Amanang:Laser e tiileng ea boemo bo tiileng ea CW e pompetsoeng ke diode e nang le bolelele ba 1064nm

Ho tjheseletsa ka Laser ea Faeba e Matla a Phahameng

Li-laser tse nang le maqhubu a bolelele ba limithara tse ka bang 1000 nm, tse nang le boleng bo botle ba mahlaseli le matla a phahameng, li sebelisoa ho tjheseletsa ka laser ea lesoba la senotlolo bakeng sa litšepe. Li-laser tsena li fetola le ho qhibilihisa thepa ka mokhoa o atlehang, li hlahisa li-weld tsa boleng bo holimo (Salminen, Piili, & Purtonen, 2010).

Ho Kopanya Ts'ebetso ea Laser le Mahlale a Mang

Ho kopanngoa ha ts'ebetso ea laser le mahlale a mang a tlhahiso, joalo ka ho roala le ho sila, ho lebisitse lits'ebetsong tsa tlhahiso tse sebetsang hantle le tse feto-fetohang haholoanyane. Ho kopanngoa hona ho molemo haholo liindastering tse kang tlhahiso ea lisebelisoa le li-die le tokiso ea enjene (Nowotny et al., 2010).

Ts'ebetso ea Laser Masimong a Hlahang

Tšebeliso ea theknoloji ea laser e atolohela masimong a macha joalo ka liindasteri tsa semiconductor, ponts'o le lifilimi tse tšesaane, e fanang ka bokhoni bo bocha le ho ntlafatsa thepa ea thepa, ho nepahala ha sehlahisoa le ts'ebetso ea sesebelisoa (Hwang et al., 2022).

Mekhoa ea Nakong e Tlang ea ho Sebetsa ka Laser

Tsoelo-pele ea nakong e tlang theknolojing ea ts'ebetso ea laser e shebane le mekhoa e mecha ea tlhahiso, ho ntlafatsa boleng ba sehlahisoa, ho etsa boenjiniere likarolo tse kopantsoeng tsa thepa e mengata le ho ntlafatsa melemo ea moruo le ea ts'ebetso. Sena se kenyelletsa tlhahiso e potlakileng ea laser ea meaho e nang le masoba a laoloang, ho tjheseletsa ka lebasetere, le ho seha maqephe a tšepe ka lesetara (Kukreja et al., 2013).

Theknoloji ea ho sebetsana le laser, ka lits'ebetso tsa eona tse fapaneng le boqapi bo tsoelang pele, e bopa bokamoso ba tlhahiso le ts'ebetso ea thepa. Ho tenyetseha ha eona le ho nepahala ha eona ho e etsa sesebelisoa sa bohlokoa liindastering tse fapaneng, e sutumelletsa meeli ea mekhoa ea tlhahiso ea setso.

Lazov, L., Angelov, N., & Teirumnieks, E. (2019). MOKHOA OA HO KHAKISA PELE HO MATLA A BOHLOKOA MEKHOENG EA THEKNOLOJI EA LASER.TIKOLOHO. THEKNOLOJI. MEHLOLI. Litlaleho tsa Seboka sa Machabeng sa Saense le Sebetsang. Sehokelo

Patel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., & Bovatsek, J. (2011). Tlhahiso e Potlakileng ea Lisele tsa Letsatsi tsa Laser Doping tse Khethehileng tse Sebelisang Leqhubu le Tsoelang Pele la 532nm (CW) le Mehloli ea Laser ea Quasi-CW e koetsoeng.Sehokelo

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). DUV matla a phahameng a lasers a sebetsa bakeng sa khalase le CFRP.Sehokelo

Moon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., & Kim, K.-S. (1999). Maqhubu a sebetsang a intracavity a imena habeli ho tsoa ho laser ea Nd:YAG e phatsimang ka lehlakoreng e sebelisang kristale ea KTP.Sehokelo

Salminen, A., Piili, H., & Purtonen, T. (2010). Litšobotsi tsa matla a phahameng a fiber laser welding.Litlaleho tsa Setheo sa Baenjiniere ba Mekaniki, Karolo ea C: Koranta ea Saense ea Boenjiniere ba Mekaniki, 224, 1019-1029.Sehokelo

Majumdar, J., & Manna, I. (2013). Selelekela sa Tlhahiso ea Lisebelisoa tse Thusitsoeng ke Laser.Sehokelo

Gong, S. (2012). Diphuputso le ditshebediso tsa theknoloji e tswetseng pele ya ho sebetsana le laser.Sehokelo

Yumoto, J., Torizuka, K., & Kuroda, R. (2017). Ntlafatso ea Bethe ea Teko ea Tlhahiso ea Laser le Database bakeng sa Ts'ebetso ea Lisebelisoa tsa Laser.Tlhahlobo ea Boenjiniere ba Laser, 45, 565-570.Sehokelo

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). Tsoelo-pele ho thekenoloji ea ho shebella in-situ bakeng sa ts'ebetso ea laser.SCIENTIA SINICA Physica, Mechanica & Astronomica. Sehokelo

Sun, H., & Flores, K. (2010). Tlhahlobo ea Sebopeho sa Microstructural ea Khalase ea Tšepe e Thehiloeng ho Zr e Sebelisitsoeng ka Laser.Litšebelisano tsa Tšepe le Thepa A. Sehokelo

Nowotny, S., Muenster, R., Schharek, S., & Beyer, E. (2010). Sele e kopaneng ea laser bakeng sa ho koahela le ho sila ka laser e kopaneng.Boiketsetso ba Kopano, 30(1), 36-38.Sehokelo

Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., & Rao, BT (2013). Mekhoa e Hlahang ea ho Sibolla Lisebelisoa tsa Laser bakeng sa Litšebeliso tsa Liindasteri tsa Nakong e Tlang.Sehokelo

Hwang, E., Choi, J., & Hong, S. (2022). Mekhoa e mecha ea vacuum e thusoang ke laser bakeng sa tlhahiso e nepahetseng haholo le e nang le chai e ngata.Sekala se senyenyane. Sehokelo

Nako ea poso: Pherekhong-18-2024