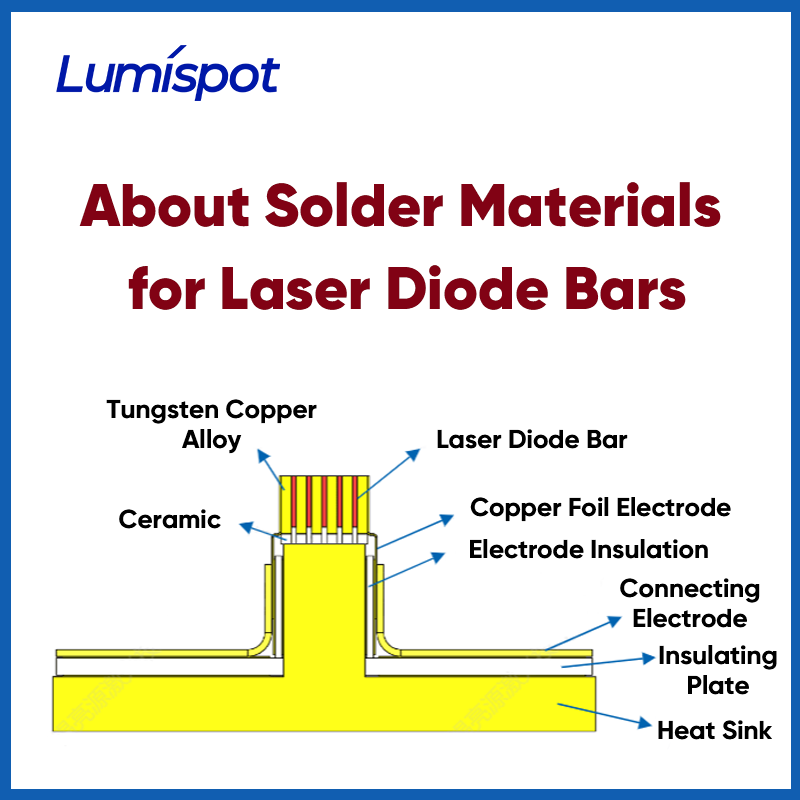

Moralong le tlhahisong ea li-laser tsa semiconductor tse matla a phahameng, li-laser diode bars li sebetsa e le li-unit tsa mantlha tse ntšang leseli. Tshebetso ea tsona ha ea itšetleha feela ka boleng ba mantlha ba li-chip tsa laser empa hape e itšetlehile haholo ka ts'ebetso ea ho paka. Har'a likarolo tse fapaneng tse amehang ho paketeng, thepa ea solder e bapala karolo ea bohlokoa e le sebopeho sa mocheso le motlakase pakeng tsa chip le sinki ea mocheso.

1. Karolo ea Solder ho Li-Diode tsa Laser

Hangata li-emitter tsa laser diode li kopanya li-emitter tse ngata, e leng se fellang ka matla a mangata le litlhoko tse thata tsa taolo ea mocheso. Ho fihlela ho qhala ha mocheso ka katleho le botsitso ba sebopeho, thepa ea ho solder e tlameha ho fihlela litekanyetso tse latelang:

① Mocheso o phahameng oa ho khanna:

E netefatsa phetiso e sebetsang hantle ea mocheso ho tsoa ho chip ea laser.

② Ho nosetsa ho molemo:

E fana ka tlamo e tiileng pakeng tsa chip le substrate.

③ Sebaka se loketseng sa ho qhibiliha:

E thibela phallo kapa ho senyeha ha lintho nakong ea ts'ebetso kapa ts'ebetso e latelang.

④ Koefficient e lumellanang ea katoloso ea mocheso (CTE):

E fokotsa khatello ea mocheso ho chip.

⑤ Ho hanyetsa mokhathala hantle haholo:

E lelefatsa bophelo ba tšebeletso ea sesebelisoa.

2. Mefuta e Tloaelehileng ea Solder bakeng sa ho Paka Lipakete tsa Laser Bar

Tse latelang ke mefuta e meraro e meholo ea thepa ea ho qhibilihisa e sebelisoang haholo ho paketeng ea li-laser diode bars:

①Motsoako oa Khauta-Tin (AuSn)

Thepa:

Sebopeho sa eutectic sa 80Au/20Sn se nang le ntlha ya ho qhibiliha ya 280°C; ho tsamaisa mocheso ka matla a phahameng le matla a mechini.

Melemo:

Botsitso bo botle ba mocheso o phahameng, bophelo bo bolelele ba mokhathala oa mocheso, ha bo na tšilafalo ea lintho tse phelang, bo tšepahala haholo

Likopo:

Litsamaiso tsa laser tsa indasteri tsa sesole, tsa lifofane le tsa maemo a holimo.

②Indium e Hloekileng (Ka Hare)

Thepa:

Boemo ba ho qhibiliha ba 157°C; bo bonolo ebile bo bonolo ho bopeha.

Melemo:

Tshebetso e phahameng ka ho fetisisa ya ho potoloha ha mocheso, kgatello e tlase hodima chip, e loketse ho sireletsa meaho e senyehang habonolo, e loketse ditlhoko tsa ho tlamahana mochesong o tlase

Meeli:

E sekametse ho oxidation; e hloka sepakapaka se sa sebetseng nakong ea ts'ebetso, matla a tlase a mechini; ha e loketse lits'ebetso tse nang le mojaro o mongata

③Mekhoa ea ho Solder e Kopantsoeng (mohlala, AuSn + In)

Sebopeho:

Ka tlwaelo, AuSn e sebediswa ka tlasa chip bakeng sa ho kgomarela ka matla, ha In e sebediswa ka hodimo bakeng sa ho ntlafatsa ho buffer ha mocheso.

Melemo:

E kopanya ho tšepahala ho hoholo le phomolo ea khatello ea maikutlo, e ntlafatsa ho tšoarella ha liphutheloana ka kakaretso, e ikamahanya hantle le maemo a fapaneng a ts'ebetso

3. Tšusumetso ea Boleng ba Solder Tshebetsong ea Sesebelisoa

Khetho ea thepa ea ho rekisetsa le taolo ea ts'ebetso li ama haholo ts'ebetso ea electro-optical le botsitso ba nako e telele ba lisebelisoa tsa laser:

| Ntlha ea Solder | Tšusumetso ho Sesebelisoa |

| Ho tšoana ha lera la solder | E ama kabo ea mocheso le botsitso ba matla a optical |

| Sekhahla sa lefeela | Likheo tse phahameng li lebisa ho ho hanyetsa mocheso o eketsehileng le ho chesa haholo sebakeng seo. |

| Bohloeki ba motsoako | Litšusumetso tsa ho qhibiliha botsitso le ho hasana ha methapo ea tšepe |

| Ho koloba ha sefahleho | E khetholla matla a ho kopanya le ho tsamaisa mocheso oa sebopeho |

Tlas'a ts'ebetso e tsoelang pele ea matla a phahameng, esita le liphoso tse nyane ho kopanyeng ha litšepe li ka lebisa ho bokellaneng ha mocheso, e leng se fellang ka ho senyeha ha ts'ebetso kapa ho hloleha ha sesebelisoa. Ka hona, ho khetha ho kopanya ha boleng bo holimo le ho kenya tšebetsong lits'ebetso tse nepahetseng tsa ho kopanya ke tsa bohlokoa ho fihlelleng liphutheloana tsa laser tse tšepahalang haholo.

4. Mekhoa le Nts'etsopele ea Nakong e Tlang

Ha mahlale a laser a ntse a tsoela pele ho kenella ts'ebetsong ea indasteri, opereishene ea bongaka, LiDAR le masimo a mang, thepa ea solder bakeng sa liphutheloana tsa laser e ntse e fetoha ka litsela tse latelang:

①Ho kopanya ka mocheso o tlase:

Bakeng sa ho kopanngoa le thepa e utloang mocheso

②Solder e se nang loto:

Ho fihlela melaoana ea RoHS le melaoana e meng ea tikoloho

③Lisebelisoa tsa sebopeho sa mocheso tse sebetsang hantle (TIM):

Ho fokotsa ho hanyetsa mocheso haholoanyane

④Mahlale a ho kopanya lintho tse nyane:

Ho tšehetsa miniaturization le kopanyo ea bongata bo boholo

5. Qetello

Leha di le nyane ka bophahamo, thepa ya ho sotha ke dihokelo tsa bohlokwa tse netefatsang tshebetso le botshepehi ba disebediswa tsa laser tse matla a hodimo. Ha ho kenngwa di-laser diode bar, ho kgetha sotha e nepahetseng le ho ntlafatsa tshebetso ya ho kopanya ke tsa bohlokwa ho fihlella tshebetso e tsitsitseng ya nako e telele.

6. Mabapi le Rona

Lumispot e ikemiselitse ho fa bareki likarolo tsa laser tsa profeshenale le tse tšepahalang le litharollo tsa ho paka. Ka boiphihlelo bo bongata ba ho khetha thepa ea solder, moralo oa tsamaiso ea mocheso, le tlhahlobo ea ts'epo, re lumela hore ntlafatso e 'ngoe le e 'ngoe ka botlalo e bula tsela ea ho fihlela bokhabane. Bakeng sa tlhaiso-leseling e batsi ka theknoloji ea ho paka laser e matla haholo, ikutloe u lokolohile ho ikopanya le rona.

Nako ea poso: Phupu-07-2025