Theknolojing ea sejoale-joale ea optoelectronic, li-laser tsa semiconductor li hlahella ka sebopeho sa tsona se senyenyane, bokhoni bo phahameng, le karabelo e potlakileng. Li bapala karolo ea bohlokoa masimong a kang puisano, tlhokomelo ea bophelo bo botle, ts'ebetso ea indasteri, le ho lemoha/ho lekola. Leha ho le joalo, ha ho buuoa ka ts'ebetso ea li-laser tsa semiconductor, parameter e le 'ngoe e bonahalang e le bonolo empa e le ea bohlokoa haholo - potoloho ea mosebetsi - hangata e hlokomolohuoa. Sengoloa sena se kenella ka hare ho mohopolo, lipalo, litlamorao, le bohlokoa bo sebetsang ba potoloho ea mosebetsi lits'ebetsong tsa laser tsa semiconductor.

1. Potoloho ea Mosebetsi ke Eng?

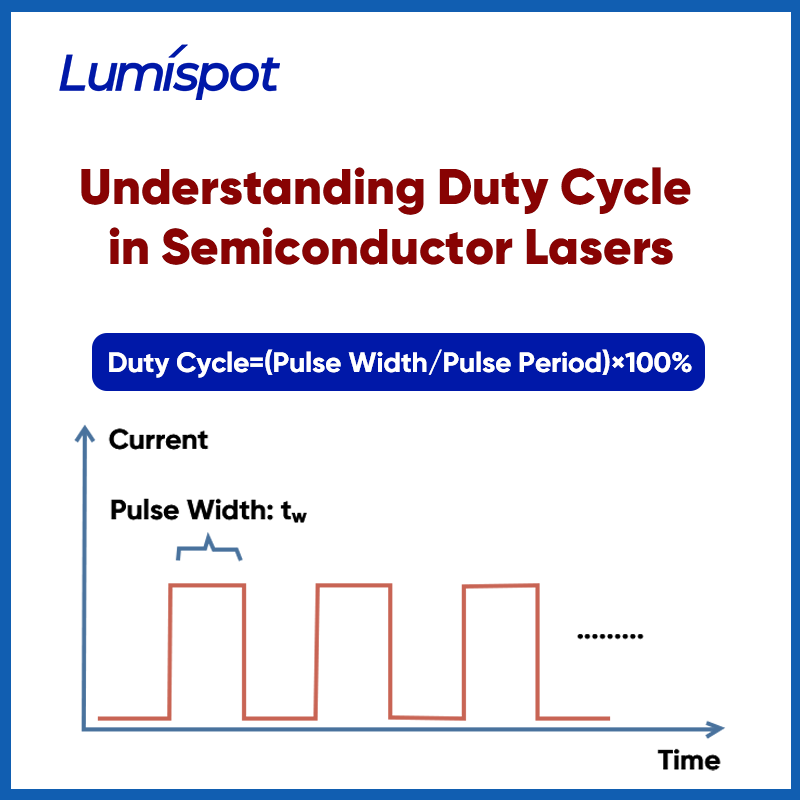

Potoloho ea mosebetsi ke karolelano e se nang tekanyo e sebelisetsoang ho hlalosa karolo ea nako eo laser e leng boemong ba "ho" nakong e le 'ngoe ea lets'oao le pheta-phetoang. Hangata e hlahisoa e le peresente. Foromo ke: Potoloho ea Mosebetsi = (Bophara ba Pulse/Nako ea ho otla ha pelo)×100%. Mohlala, haeba laser e ntša pulse ea 1-microsecond metsotsoana e meng le e meng e 10, potoloho ea mosebetsi ke: (1 μs/10 μs)×100%=10%.

2. Ke Hobane'ng ha Potoloho ea Mosebetsi e le ea Bohlokoa?

Leha e le karolelano feela, potoloho ea mosebetsi e ama ka kotloloho tsamaiso ea mocheso ea laser, nako ea bophelo, matla a tlhahiso, le moralo oa sistimi ka kakaretso. A re hlahlobisiseng bohlokoa ba eona:

① Tsamaiso ea Thermal le Sesebelisoa Bophelo bohle

Mesebetsing ea ho pulsa ka maqhubu a phahameng, potoloho ea mosebetsi o tlase e bolela linako tse telele tsa "ho tima" lipakeng tsa li-pulse, e leng se thusang laser ho phola. Sena se molemo haholo lits'ebetsong tse nang le matla a mangata, moo ho laola potoloho ea mosebetsi ho ka fokotsang khatello ea mocheso le ho lelefatsa bophelo ba sesebelisoa.

② Matla a ho Hlahisa le Taolo ea Matla a Optical

Potoloho e phahameng ea mosebetsi e fella ka tlhahiso e phahameng ea optical, ha potoloho e tlase ea mosebetsi e fokotsa matla a tloaelehileng. Ho fetola potoloho ea mosebetsi ho lumella ho lokisoa ha matla a tlhahiso ntle le ho fetola hona joale ea peak drive.

③ Karabelo ea Sistimi le Phetoho ea Matšoao

Litsamaisong tsa puisano ea optical le tsa LiDAR, potoloho ea mosebetsi e susumetsa ka ho toba nako ea karabelo le merero ea modulation. Mohlala, ho range ea laser e nang le pulsed, ho beha potoloho e nepahetseng ea mosebetsi ho ntlafatsa ho lemoha lets'oao la echo, ho ntlafatsa ho nepahala ha tekanyo le makhetlo.

3. Mehlala ea Ts'ebeliso ea Potoloho ea Mosebetsi

① LiDAR (Ho Lemoha le ho Fapana ha Laser)

Li-moduleng tsa laser tsa 1535nm, tlhophiso ea pulse ea potoloho e tlase, e nang le tlhōrō e phahameng hangata e sebelisoa ho netefatsa ho fumanoa ha sebaka se selelele le polokeho ea mahlo. Lipotoloho tsa mosebetsi hangata li laoloa pakeng tsa 0.1% le 1%, ho leka-lekanya matla a phahameng a tlhōrō le ts'ebetso e sireletsehileng le e pholileng.

② Li-laser tsa Bongaka

Litšebelisong tse kang kalafo ea letlalo kapa opereishene ea laser, lipotoloho tse fapaneng tsa mosebetsi li fella ka litlamorao tse fapaneng tsa mocheso le liphello tsa kalafo. Potoloho ea mosebetsi o phahameng e baka ho futhumatsa ho tsoelang pele, ha potoloho ea mosebetsi o tlase e tšehetsa ho tlosoa ha pulse hang-hang.

③ Ts'ebetso ea Lisebelisoa tsa Liindasteri

Ho tshwayeng le ho tjheseletsa ka laser, potoloho ya mosebetsi e ama tsela eo matla a kenngwang ka yona thepa. Ho fetola potoloho ya mosebetsi ke senotlolo sa ho laola botebo ba ho betla le ho kenella ha ho tjheseletsa.

4. Mokhoa oa ho Khetha Potoloho e Nepahetseng ea Mosebetsi?

Potoloho e ntle ea mosebetsi e itšetlehile ka ts'ebeliso e itseng le litšobotsi tsa laser:

①Potoloho ea Mosebetsi o Tlase (<10%)

E loketse lits'ebetso tsa ho otla ha pelo ka nako e telele, tse nang le ho otla ha pelo ho hokhutšoanyane joalo ka ho chencha kapa ho tšoaea ka nepo.

②Potoloho ea Mosebetsi o Mahareng (10%–50%)

E loketse litsamaiso tsa laser tse pheta-phetoang haholo.

③Potoloho ea Mosebetsi o Phahameng (>50%)

E atamela ts'ebetso ea maqhubu a tsoelang pele (CW), e sebelisoang lits'ebetsong tse kang ho pompa ha optical le puisano.

Lintlha tse ling tseo u lokelang ho li nahana li kenyelletsa bokhoni ba ho qhala mocheso, ts'ebetso ea potoloho ea mokhanni, le botsitso ba mocheso oa laser.

5. Qetello

Le hoja e le nyane, potoloho ea mosebetsi ke parameter ea bohlokoa ea moralo litsamaisong tsa laser tsa semiconductor. Ha e ame feela tlhahiso ea ts'ebetso empa hape le botsitso ba nako e telele le ts'epo ea sistimi. Nts'etsopele le ts'ebeliso ea laser nakong e tlang, taolo e nepahetseng le ts'ebeliso e tenyetsehang ea potoloho ea mosebetsi e tla ba tsa bohlokoa ho ntlafatseng ts'ebetso ea sistimi le ho nolofalletsa boqapi.

Haeba o na le lipotso tse ling mabapi le moralo kapa lits'ebetso tsa liparamente tsa laser, ikutloe u lokolohile ho ikopanya le rona kapa ho siea maikutlo. Re mona ho thusa!

Nako ea poso: Phupu-09-2025